Saw Cutting

Our in-house saw cutting capability offers the best raw materials and turnaround for our customers’ needs. Our saw cutting capabilities can handle production cuts and bundle cutting.

Steelcrest Precision offers a robust set of additional precision machining and fabrication services to solve your business challenges. From rapid prototyping to reverse engineering to quality control, we’re ready to help you.

Our in-house saw cutting capability offers the best raw materials and turnaround for our customers’ needs. Our saw cutting capabilities can handle production cuts and bundle cutting.

Our welding capabilities include mig and tig capabilities, as well as access to an arsenal of partners to solve your welding needs.

Our heat treating and tempering services are carried out in furnaces that can reach temperatures as high as 2100° F. Heat treating and tempering are efficient ways to improve product strength and hardness or to soften metals per application requirements. Heat treating applications include:

The Tykma Vereo Fiber Laser Marker with a rotary attachment allows us to etch a variety of font styles and sizes, company logos, and photographs on flat and round surfaces.

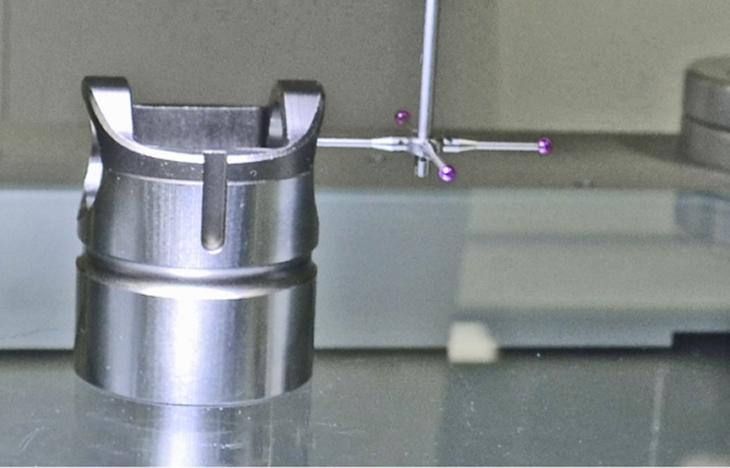

Our state-of-the art Quality Control lab includes FaroArm CMM and LLP capabilities as well as coordinate measurement machines with vision. This equipment can be used for 3D inspections, CAD comparison, dimensional analysis, reverse engineering, and more.

Steelcrest Precision is equipped to design and produce prototype parts for our customers, which is ideal for testing fit and functionality of a part prior to production. Durable, fully-functional parts are built by importing a 3D file into one of our 3D printers.

Using FARO Arm with metrology lab technology, the Wauseon Machine team helps customers with their reverse engineering needs and projects. Our team has extensive experience with reverse engineering.

Carbinite is a tungsten carbide that can be applied to most metals using Electro Spark Deposition. This process increases friction, reduces wear, improves grip, and improves performance. Wauseon Machine uses Carbinite on collects, clamp blocks, and other tooling. This increases quality and reduces costs for our customers, due to the extended lifetime of tooling and fixtures.

Discover our end-to-end precision machining and fabrication capabilities.